Overview

The Concordia University Centre for Creative Reuse (CUCCR) originated in March 2017, rooted in the Art Education Master’s thesis of its founder, Anna Timm-Bottos. Inspired by her research into Canadian creative reuse case studies and similar projects in Toronto and Winnipeg, Timm-Bottos sought to introduce a formal material diversion model to Concordia. The project initially gained momentum by winning the “Big Hairy Idea” competition hosted by the Concordia Council on Student Life (CCSL) and secured vital early funding from the Sustainability Action Fund. With additional support from Environmental Health and Safety (EHS) and Facilities Management, the initiative transformed an abandoned 800-square-foot storage locker in the Henry F. Hall Building basement into its first functional depot. Since these humble beginnings, CUCCR has grown significantly, relocating its main operations to the Grey Nuns Building in 2019 and expanding into specialized satellite spaces to better serve the university community.

Team

Anna Timm-Bottos, co-founder Reuse Programming & Sustainability Specialist

Arrien Weeks, co-founder and Sustainability Technician (among other roles)

Since 2017

Interns (for credit/paid): over 30 across all disciplines

Volunteers: over 3000 volunteer hours

The original build

In December of 2016, I was hired to build the first reuse depot going off of a student’s intern plans and my own design and building experience. Along with physical build, I also built the original metric tracking system using the content management system, WordPress.

Tools

Table saw, mitre saw, drills, clamps, paint brush

Materials

Wood (sourced mainly from the Design department, other fine arts departments/programs and loading docs. Screws/bolts (recuperated). Wheels (purchased). Scale (purchased).

The Grey Nuns Depot

By fall of 2017, we were bursting at the seams in the basement of the Hall building. a colleague in Facilities Management made us aware that there was some unused space in the GN building, the nuns old laundry room.

By fall 2019 we had accessed and renovated the space. We worked with various stakeholders on and off campus to have it re-plumbed, painted, repaired and made accessible.

Outcome and Impact

The outcome of building a reuse centre in a university is how much it has brought students, staff faculty and administrators together towards a common goal, changing the culture of reuse. It has pushed curriculum in new directions, changed purchasing policies and saved the university money.

Material and Financial Impact

Since day one, collecting impact metrics has been central to the centre’s mission. Initially they were collected with a very detailed custom built tracking system. In late 2024, the system was changed based on a lot of introspection and analysis of what was truly important. What’s come from this is the Centre’s Impact page.

Academic Impact

In the early days it started with class presentations, mostly in departments that generated waste from making.

By March 2024, CUCCR was integrated in multiple ways across over 60 courses in all four faculties. This was possible due to the relationships built with faculty, staff and administrators over the course of seven years.

As of January 2026, CUCCR is now mentioned, integrated into syllabi and embraced in over 300 courses across all four faculties at Concordia University.

Artistic impact

Engaged over 700 artists/makers/designers since 2017 in making with used/found materials through artist residencies, skill-shares and workshops.

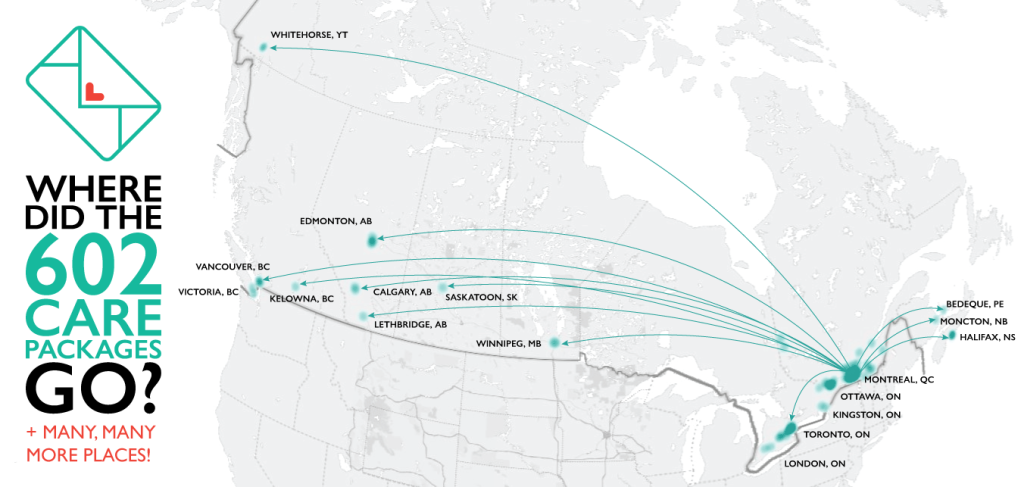

The Care Package Project was the COVID pandemic version of the artist residency which saw 602 packages go out to artist and makers from across Canada. We reconnected over Zoom with big help from the 4th Space and made together in a sort of collective healing process.

Concordia NOW Article, March 22, 2021

Concordia NOW Article, December 3, 2020

Leave a Reply